The life cycle of Novoceram products

1/ Raw materials and energy

2/ Production

3/ Trasportation

4/ Use

5/ Disposal

1/ Raw materials and energy

1.1/ Choice of raw materials

Raw materials

- Novoceram products are 100% environmentally friendly. The raw materials of the mix are natural products such as clays, feldspars, quartz, kaolin and natural mineral dyes.

- 0% carcinogenic, mutagenic or reprotoxic substances. All carcinogenic, mutagenic or reprotoxic substances (such as lead, cadmium and other heavy metals) usually associated with ceramic production have been removed from the production process and from all Novoceram products. The decision to take such a drastic step reduces the possibility that such substances can be released into the atmosphere and reduces the chance of coming into contact with them while handling the products and eliminates the possibility to harming the environment, the health of staff working in the production department and those who live in the environments where the products are installed.

- 100% of the raw material of the ceramic mix comes from quarries outside Natura 2000 areas. The raw materials of the ceramic mix come from quarries that are regularly verified by the competent authorities. The quarries are outside the « Natura 2000 » areas, be they land or sea, that European Union member states have identified as areas where indigenous species (plant or animal) and their natural habitats are rare or classified as being in danger.

- 70% of the raw materials of the ceramic mix come from France. The rest is transported by sea and by river to significantly reduce the carbon footprint of transportation of these materials.

- The internal recycling of the raw waste signifies a decrease of raw materials used and a more prudent use of natural resources.

- 100% of the materials used for the production of cardboard and packaging come from the recycling supply chain.

- Careful selection of socially responsible suppliers. Novoceram is aware that environmental sustainability over time depends on, amongst other things, the careful selection of the suppliers, taking into consideration their sensitivity to environmental issues and ethics of their business policies.

1.2/ Energy

- Energy consumption optimization. Novoceram has implemented a policy of energy management in compliance with NF EN ISO 50001 regulations. Various projects have been approved, such as the recovery of the heat from the kilns to feed the atomizers to save on gas consumption, the replacement of all light fixtures to best manage the illumination of the factory and outdoor areas, and the implementation of a real-time monitoring program that means being able to optimize all significant energy consumption.

- Optimization of the lighting system. Novoceram has undertaken the constant replacement of the light fixtures with energy saving equipment, both outside and inside the factory, office building and showroom. In the new logistic center and in the new production lines introduced since 2015, Novoceram uses an intelligent LED lighting system that saves 82% of electric energy on an annual basis.

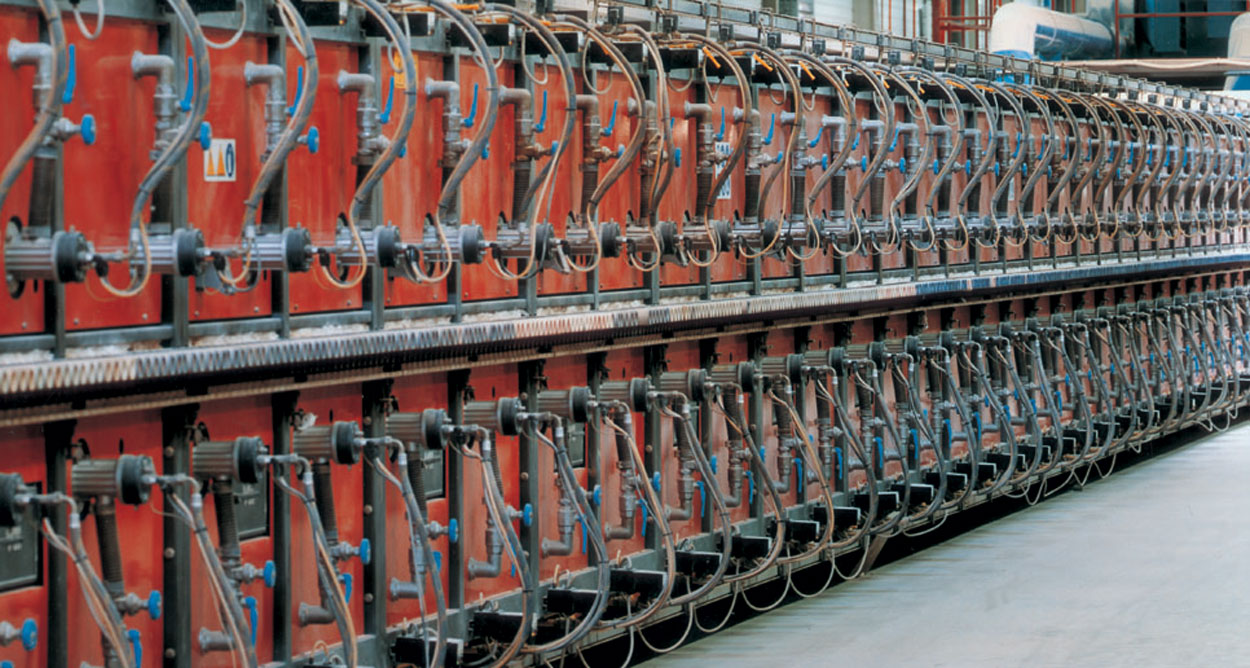

2/ Production

2.1/ Air

Reduction of emissions of CO2

- Reduction of emissions into the atmosphere. Emissions into the atmosphere have been reduced to minimum levels. Novoceram has invested in the most avant-garde dust emission and polluting gas disposal plants. This type of technology means being able to reduce the environmental impact of the production process.

- Constant improvement of indoor air quality. For many years now Novoceram has been committed to improving the working conditions of its employees, in particular to the constant improvement of the air quality inside the factory. Over the past 10 years the silica level inside the factory has dropped by more than 85% in the most exposed areas thanks to daily cleaning and to the installation of vacuum systems in strategic areas. Conscious of the many benefits of Corporate Social Responsibility, Novoceram takes into account all factors that may impact not only on the environment, but also on the well-being of its employees.

2.2/ Water

100% of industrial water is recycled

- The factory recycles all its industrial water. Thanks to the investments made in production machinery, Novoceram treats and recycles all water used in the manufacturing process, in this way significantly reducing the consumption of this precious natural resource and no waste water is put back into the water table. Each year Novoceram treats the equivalent of 30,000,000 1 liter bottles of water.

2.3/ Waste

- 100% of the raw waste from the pre-firing industrial process is recycled. The ceramic tiles discarded from production before firing are reintroduced into the production process. This practice means a reduction in the consumption of raw materials.

- 100% fired waste is recycled. Fired waste, which cannot be reintroduced into the production process, is also recycled outside the ceramic industry and used to make roads sub-beds or to fill in mined out quarries. Moreover, unlike other finishing materials with a high environmental impact that must be disposed of in landfills or by ways of refuse-to-energy incinerators, the removed ceramic waste is inert and does not represent an environmental hazard.

- Recycling of 99% of waste produced. For many years Novoceram has embarked on a path oriented to the containment of waste of all resources, in particular the reduction of the amounts of generated where the recovery rate is approaching 100%. Since 2009 the collection of differentiated waste has seen a drop of 40% of general industrial waste.

2.4/ Management systems

ISO 9001 (quality), ISO 14001 (environment), ISO 50001 (energy) certifications

- Corporate policies have been set down in the NF EN ISO 14001 and NF EN ISO 9001 management systems since 2009. The energy management system in accordance with NF EN ISO 50001 has instead been implemented since 2015. Novoceram is conscious of the considerable advantages of these management systems: the aim is to integrate the company into its environment by taking control of the interests of all parties involved, from supplier to customer through the local authorities, neighbors, co-workers with a long-term view.

- Corporate Social Responsibility (CSR). Novoceram is an ethical and transparent company. In the light of this the company acts in the following way:

- On environmental impacts: air, water, refuse, energy, transportation and choice of raw materials within the framework of the quality management systems, the environment and energy.

- On social issues: respect for human rights, working conditions, dialogue with and motivation of employees, equality and non-discrimination are part of the company principles which ensure the future of the company.

- On economic issues: CSR is not only about social and environmental issues, but also examines the heart of the business of the enterprise. For instance, the relationship with customers and suppliers are essential. For a company it is vital to focus on ethical business practices and invest in intangible capital to ensure the long-term sustainability of the company.

3/ Transportation

Effective logistics

- Novoceram customers are local customers. A significant advantage of Novoceram is that of being located geographically at the heart of its sales area. The impact of transportation of ceramic tiles is rather high due to the weight of the products in question. Buying a Novoceram product in France or in a neighboring country considerably reduces the carbon footprint connected with transportation.

- Transportation is optimized. Novoceram constantly implements projects and ideas to optimize the transportation of goods, from the production site to the distribution site. Moreover, in some cases transportation by rail can be used to further reduce the carbon footprint connected to transportation.

4/ Use

Kobe Graphite – Novoceram

- Ceramic tiles are inert. The intrinsic properties of ceramic tiles and the choice of raw materials free of heavy metals make them totally inert products, not only for the environment but also on the health of the end user.

- No emission into the atmosphere during use. The absence of the so called “CMR” raw materials means that no harmful substances are emitted. Tests prove that Novoceram ceramic tiles do not release lead, cadmium, and prove the absence of these elements in the raw materials (NF EN ISO 10545-15). Furthermore, the products are A+ classified according to the labeling certifications currently in force: ceramic tiles, by their very nature and construction, do not emit any Volatile Organic Compound. Such elements, destroyed at temperatures lower than 200°C, if present, are completely eliminated during firing, when temperatures can reach in excess of 1200°C.

- As well as environmental certifications, the Novoceram range is NF UPEC certified.

- Novoceram has a transparent and communicative approach. The end user can make direct inquiries of the environmental benefits of choosing Novoceram products.

5/ Disposal

- 100% of the packaging is recyclable. The materials used for the packaging of the ceramic tiles are all recyclable: paper, cardboard, wood and plastic can all be recycled.

- Novoceram ceramic tiles are inert. They can be disposed of harmlessly in the same way as simple building rubble.